Weld Done

Shop Workers Reflect on Their Experiences in Agricultural Mechanics

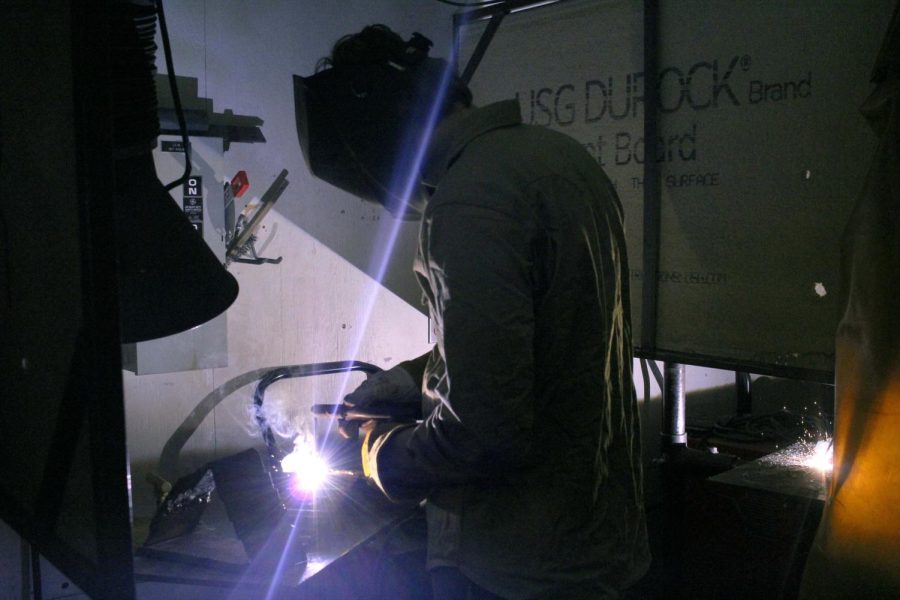

Welding a chunk of metal, sophomore Mason Kasel works on a new project while wearing his safety gear for his Agricultural Mechanics class. Safety is important in the workshop, and welders weld behind a shower curtain like a light shield. “The best part of my job is when you get a student who’s been struggling and then they have an ‘ah-ha’ moment and have this look on their face and you can see the light bulb above the head,” Russell said. “There’s a lot of kids who’ve never had tools at home so this is a whole new experience for them.”

February 15, 2022

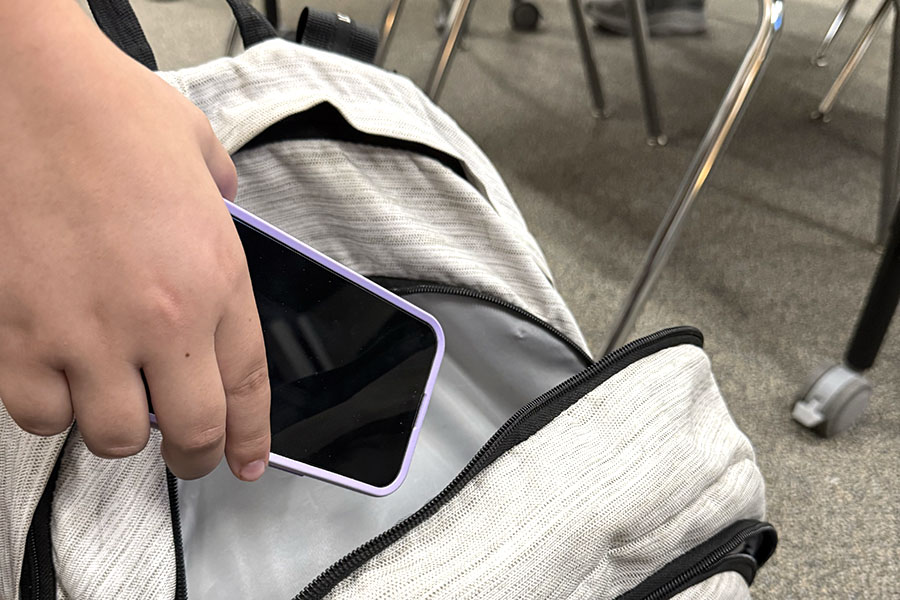

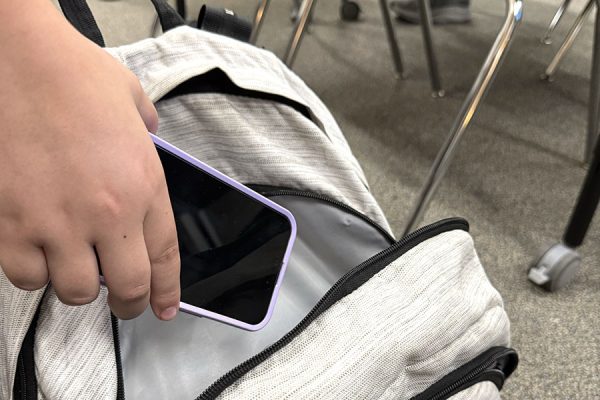

Gloves. Check. Helmet. Check. Rod. Check. Safety glasses. Check. These are just some of the basic tools used in the Agriculture Mechanics class, also often referred to as the welding class says junior Samuel Burns.

Ag Mech and Metal Tech is what a lot of students refer to as the welding class, where students get to learn a multitude of things, but the common consensus is that welding is the most fun part of the class, says junior Connor Ross.

Ag Mech isn’t just a learning and progression-based class, but there are competitions and a ‘sport’ aspect involved, as there is projects and contests that students can enter. Some have made entire 30 foot long trailers and entered them into contests, but there are many other things that are built.

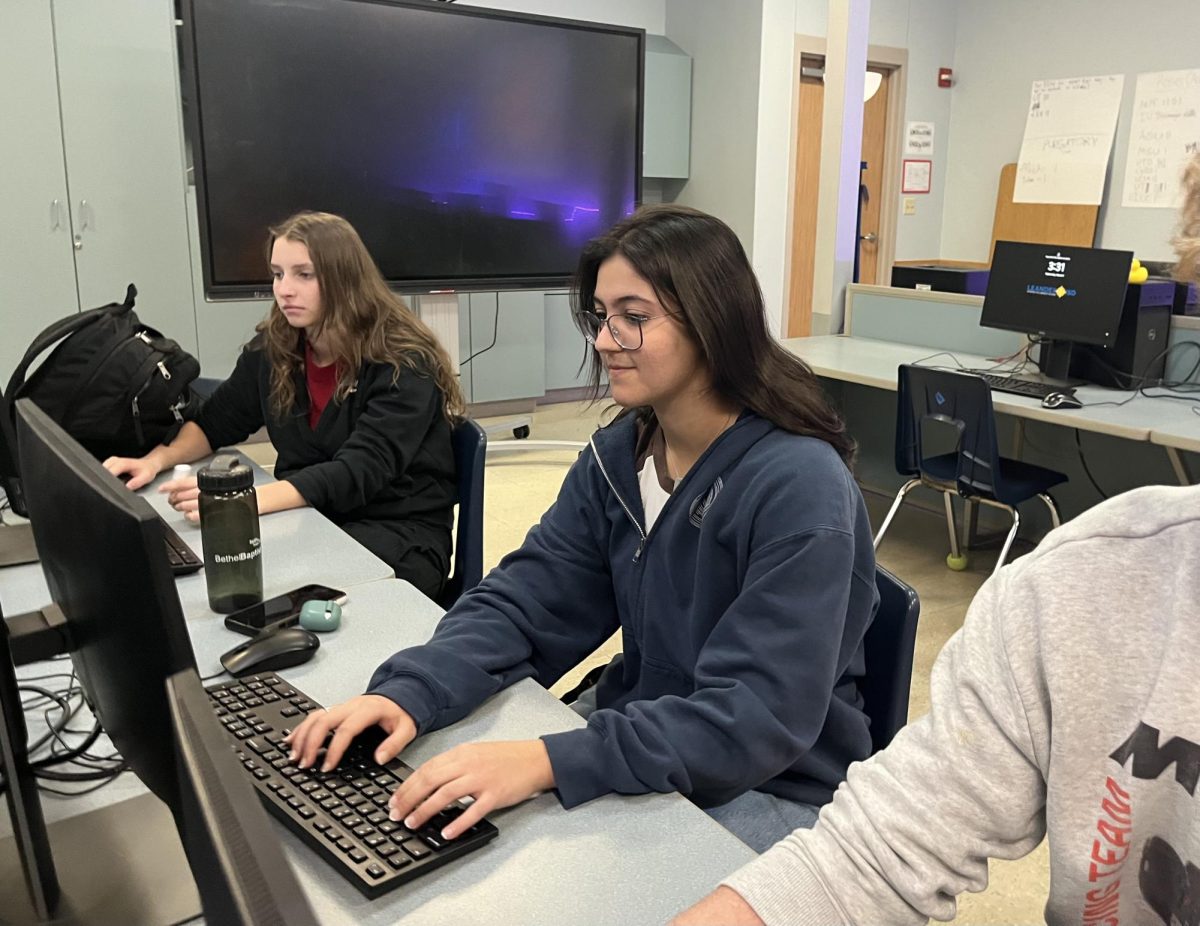

“The biggest challenge for me as a teacher is being able to have students that are teachable,” Agriculture Science teacher Myles Russell said. “It’s one of those things that you need to come in being teachable and expecting to learn because it’s a difficult process to master and become good at”.

Welding isn’t dangerous if all the safety precautions are followed, but safety is important as the welds can be melting metal at or up to 10,000 degrees Fahrenheit. Having the correct safety equipment makes the process go smoother and helps not burn the students hands or even make them go blind.

“I really like my equipment and the stuff I use daily, especially my helmet because I’ve got some hilarious stickers on it,” Burns said. “People should definitely join the class because Mr. Russell’s one of the coolest teachers.”

Russell is liked by a majority of students who he works with, through his laid-back and helpful teaching style. While also maintaining his ability to teach safely Mr. Russell creates friendships with his students says Ross.

“My favorite part about welding is definitely the teacher that’s for sure where it’s at,” Ross said. “The teacher really helps you out, especially

during your projects, which is one of the best parts, as well as him just being really funny and you want to be around him.”

Welding isn’t the main focus of the Agriculture Mechanics class, but it’s one of the most important parts for the students attending it as it opens up possibilities for future careers. The class is different from a typical welding class as it opens up the opportunity for UIL competitions and more time in skills to polish off welds, like angle grinding.

“The reason why you should join the class is it gives you a lot of freedom to express yourself and how to weld better,” Ross said. “It definitely gives you a lot of life skills and will be able to prepare you for a field of welding which to me is the best part, so out of high school I can have a nice job.”

![Jumping off the ground, senior linebacker Bennett Patton snatches the ball out of the air for an interception at Thursday’s game against Chaparral. Patton had two interceptions in the 56-14 victory, tying the school record for interceptions in a game. “I was just playing the game,” Patton said. “[I’m] going to go into next week, forget about it and stay humble.” Photo by Harper Chapman](https://cphswolfpack.com/wp-content/uploads/2025/09/bennett-interception.jpg)

![The fire department came to the school after students were evacuated when smoke started coming from the ceiling of a classroom. All students and staff are safe. “All of my friends left their stuff too, so we couldn’t contact our parents, and it was stressful,” senior Brynn Fowler said. “It was scary because I didn’t know [what was going on], and I couldn’t find anyone because it was a big crowd.” Photo by Anthony Garcia](https://cphswolfpack.com/wp-content/uploads/2025/09/firetruck.jpg)

![Sitting with her friend senior Sohpia Struve at last year’s Austin City Limits Festival, senior Ava Zuniga poses for a picture under a pavilion. They are frequent attendees at ACL, an annual music festival at Zilker Park. “I would recommend seeing a bunch of people,” Zuniga said. “This past year, we camped out for Chappell [Roan] for a really long time. I think the whole point of ACL, [which] is a lot of fun, is that you can go see so many different people, even if you don’t know them. So by camping by one person, it really limits yourself from being able to go see a bunch of people.” Photo courtesy of Ava Zuniga](https://cphswolfpack.com/wp-content/uploads/2025/10/EE9E9484-FE6F-4AA0-B5F5-0C177AB32841-1200x857.jpeg)

![Broadcast, yearbook and newspaper combined for 66 Interscholastic League Press Conference awards this year. Yearbook won 43, newspaper won 14 and broadcast took home nine. “I think [the ILPC awards] are a great way to give the kids some acknowledgement for all of their hard work,” newspaper and yearbook adviser Paige Hert said. “They typically spend the year covering everyone else’s big moments, so it’s really cool for them to be celebrated so many times and in so many different ways.”](https://cphswolfpack.com/wp-content/uploads/2025/05/edited-ILPC.jpg)

![Looking down at his racket, junior Hasun Nguyen hits the green tennis ball. Hasun has played tennis since he was 9 years old, and he is on the varsity team. "I feel like it’s not really appreciated in America as much, but [tennis] is a really competitive and mentally challenging sport,” Nguyen said. “I’m really level-headed and can keep my cool during a match, and that helps me play a bit better under pressure.” Photo by Kyra Cox](https://cphswolfpack.com/wp-content/uploads/2025/09/hasun.jpg)

![Bringing her arm over her head and taking a quick breath, junior Lauren Lucas swims the final laps of the 500 freestyle at the regionals swimming competition on date. Lucas broke the school’s 18-year-old record for the 500 freestyle at regionals and again at state with a time of 4:58.63. “I’d had my eye on that 500 record since my freshman year, so I was really excited to see if I could get it at regionals or districts,” Lucas said. “ State is always a really fun experience and medaling for the first time was really great. It was a very very tight race, [so] I was a bit surprised [that I medaled]. [There were] a lot of fast girls at the meet in general, [and] it was like a dogfight back and forth, back and forth.” Photo by Kaydence Wilkinson](https://cphswolfpack.com/wp-content/uploads/2025/03/Kaydence-2.7-23-edit-2.jpg)

![As the support team sits and poses for a photo in the cafeteria with the counseling team they eagerly wait to start their day. "We [all] seem to be a team, I get up every day and there's days where I don't want to go to work today, but I'm thankful that I have a job and I'm blessed to have what I have," Christopherson said. Photo Courtesy of Julie Weltens.](https://cphswolfpack.com/wp-content/uploads/2025/01/AF9E8470-10D7-4C91-BF28-EC8F86BAB66C-1200x852.jpeg)

![Officer Stephanie Cash is in her second year as an SRO at CPHS. “Seeing [students] grow over the years has been kind of cool,” Officer Cash said. “Freshmen that [are] all over the place and then in the next couple of years get a little more squared away and go to class and do work and start thinking about the future. Being a part of a student's growth is the best way to measure my success as an SRO.” Photo Courtesy of Cedar Park Police Department's PIO, Alicia Gallagher.](https://cphswolfpack.com/wp-content/uploads/2024/12/CPHS-SRO-900x1200.jpg)

![As he sprints with the ball, senior running back Trae Hill breaks a tackle during Friday’s 35-14 loss against the Vandegrift Vipers. Hill ran for 135 yards and two touchdowns during the game. “[Scoring] was electric,” Hill said. “It always feels good to score, but the O-line did everything.”](https://cphswolfpack.com/wp-content/uploads/2025/09/IMG_0795allie.varfb_-1200x799.jpg)

![The fire department came to the school after students were evacuated when smoke started coming from the ceiling of a classroom. All students and staff are safe. “All of my friends left their stuff too, so we couldn’t contact our parents, and it was stressful,” senior Brynn Fowler said. “It was scary because I didn’t know [what was going on], and I couldn’t find anyone because it was a big crowd.” Photo by Anthony Garcia](https://cphswolfpack.com/wp-content/uploads/2025/09/firetruck-300x200.jpg)

![Finishing her night out after attending a local concert, senior Grace Sauers smiles at the camera. She recently started a business, PrettySick, that takes photos as well as sells merch at local concert venues. Next year, she will attend Columbia Chicago College majoring in Graphic Design. “There's such a good communal scene because there [are] great venues in Austin,” Sauers said. “I'm gonna miss it in Austin, but I do know Chicago is good, it's not like I'm going to the middle of nowhere. I just have to find my footing again.” Photo Courtesy of Grace Sauers.](https://cphswolfpack.com/wp-content/uploads/2025/04/Grace-300x225.png)