Team 5052 Builds their way to Steamworks Competitions

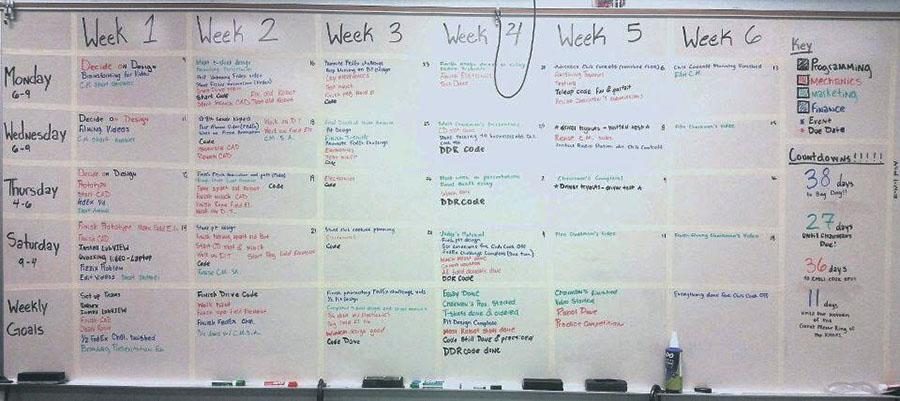

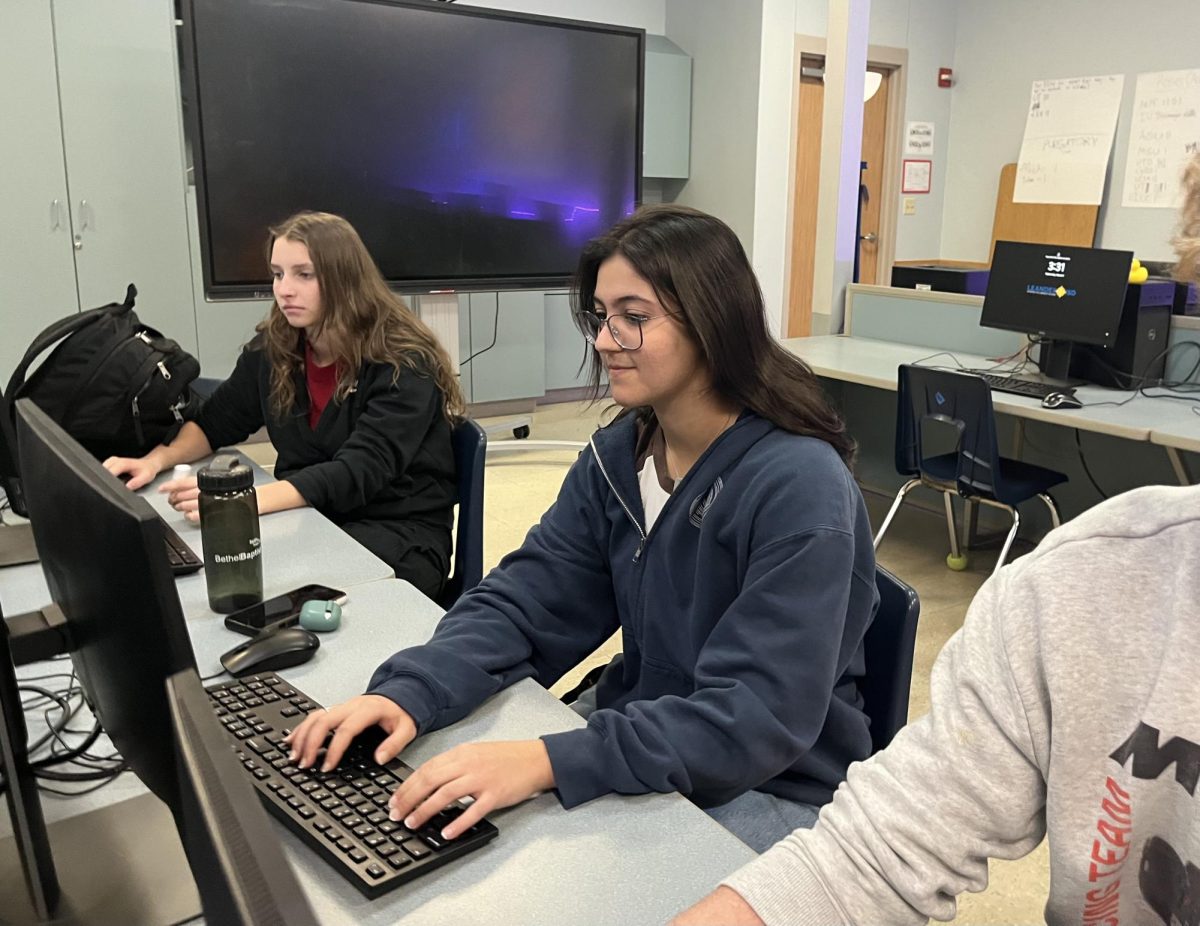

In the hectic rush of robotics build season, project manager senior Maddie Cox has constructed an elaborate schedule for the team to follow. “We do a lot of design meetings to try and figure out our plan of attack, throwing all the ideas we can think of up onto a board and picking features we like best,” Cox said.

January 19, 2017

For robotics Team 5052, build season is the most hectic, insane, and arguably, most important time of the year. Heralding the start of the robotics competition season, it begins a seven week period of long hours spent trying to build a bot to tackle the task presented by competition head, FIRST, which they will have to compete in.

This year it is “Steamworks,” a steampunk themed challenge in which teams will build robots that have to complete various tasks to prepare the airships in the middle of the field for flight. The tasks include gathering “fuel” (tennis balls) and launching them into the “boilers” (a large furnace structure with a funnel shape on top where they must get the balls). They can also collect large gears from a dispensary station and deliver them to the ship, where they will be attached to a mechanism that will make the rotors spin, and then once the challenge is over, a four foot rope descends from the airship, and the final challenge is to see what robots are able to climb it.

This year, the challenge will be done in teams of three, meaning 5052 will be paired with two other teams and must all try to work together to achieve their goals. As specialization is a key part of this challenge, the team decided to focus on the gear collecting aspect, according to project manager senior Maddie Cox.

“The trouble we’ve gotten ourselves into in the past is that we try to make a robot that can do every aspect of the challenge,” Cox said. “But this year we decided to pick two of the three and work to perfect those. We decided that gears would help us a lot because they physically can’t all be delivered with one robot, so we see ourselves as a team that could really excel in that task. We also decided to attempt climbing for the first time this year, which has the added difficulty of rope. In years past, it’s always been a bar or metal structure, so I’m excited to see how that goes.”

During build season, the team comes back to school on Mondays, Wednesdays, working from 6-9 p.m., they stay late on Thursdays, working 4-6 p.m., and they come in on Saturdays to work from 9-4 p.m. This totals up to 15 hours spent weekly on the robot, not including any time they stay late or come in early. It can get incredibly stressful to balance the commitment of robotics, schoolwork and extracurriculars, as head of business junior Will Ingarfield told us.

“The worst part for me is time management,” Ingarfield said. “Keeping on top of my schoolwork and keeping up with robotics is always a challenge, but it’s definitely worth it. I think this year it will be interesting to see the novel solutions other teams come up with. This year the robot has to climb a rope which is something FIRST has never done before. Seeing the crazy mechanisms people will come up with is always exciting.”

While the crunch time is stressful, it’s also head of hardware, senior Morgan Muir’s favorite time of year. According to Muir, build season forms a sense of unity and community among the team members.

“My best memory from build season was when we stayed up until midnight on bag day [the final day of build season],” Muir said. “After we had bagged the robot, we celebrated with Mountain Dew and cookie cake, and we didn’t leave the school until one in the morning. It was tiring, but lots of fun.”

![Posing with their UIL State Trophy, the Robolobos Van Halen Team beams with excitement after their win. “It was a team effort,” junior Noah Vo said. “I was happy because something happened in the first match and the match was also really close. So [when] they finally revealed it, I was pretty happy.” Photo courtesy of Amy Lovelace](https://cphswolfpack.com/wp-content/uploads/2025/05/IMG_0910-EDIT-1200x723.jpg)

![Broadcast, yearbook and newspaper combined for 66 Interscholastic League Press Conference awards this year. Yearbook won 43, newspaper won 14 and broadcast took home nine. “I think [the ILPC awards] are a great way to give the kids some acknowledgement for all of their hard work,” newspaper and yearbook adviser Paige Hert said. “They typically spend the year covering everyone else’s big moments, so it’s really cool for them to be celebrated so many times and in so many different ways.”](https://cphswolfpack.com/wp-content/uploads/2025/05/edited-ILPC.jpg)

![Bringing her arm over her head and taking a quick breath, junior Lauren Lucas swims the final laps of the 500 freestyle at the regionals swimming competition on date. Lucas broke the school’s 18-year-old record for the 500 freestyle at regionals and again at state with a time of 4:58.63. “I’d had my eye on that 500 record since my freshman year, so I was really excited to see if I could get it at regionals or districts,” Lucas said. “ State is always a really fun experience and medaling for the first time was really great. It was a very very tight race, [so] I was a bit surprised [that I medaled]. [There were] a lot of fast girls at the meet in general, [and] it was like a dogfight back and forth, back and forth.” Photo by Kaydence Wilkinson](https://cphswolfpack.com/wp-content/uploads/2025/03/Kaydence-2.7-23-edit-2.jpg)

![As the support team sits and poses for a photo in the cafeteria with the counseling team they eagerly wait to start their day. "We [all] seem to be a team, I get up every day and there's days where I don't want to go to work today, but I'm thankful that I have a job and I'm blessed to have what I have," Christopherson said. Photo Courtesy of Julie Weltens.](https://cphswolfpack.com/wp-content/uploads/2025/01/AF9E8470-10D7-4C91-BF28-EC8F86BAB66C-1200x852.jpeg)

![Officer Stephanie Cash is in her second year as an SRO at CPHS. “Seeing [students] grow over the years has been kind of cool,” Officer Cash said. “Freshmen that [are] all over the place and then in the next couple of years get a little more squared away and go to class and do work and start thinking about the future. Being a part of a student's growth is the best way to measure my success as an SRO.” Photo Courtesy of Cedar Park Police Department's PIO, Alicia Gallagher.](https://cphswolfpack.com/wp-content/uploads/2024/12/CPHS-SRO-900x1200.jpg)

![Taking a breath as he raises his arm up and out of the water, sophomore Kaden Padilla swims the 500 freestyle at the UIL state meet on Feb. 21-22. Padilla placed 10th overall and second in the consolation final in the event, dropping two seconds. “My family was there, so being able to drop time for them was really special,” Padilla said. “It was awesome [finding out I advanced to the consolation finals]. I wasn’t expecting it, and I was very surprised. My parents being there definitely made me a lot happier knowing they got to see me swim in finals.” Photo by Skyler King.](https://cphswolfpack.com/wp-content/uploads/2025/03/kaden-padilla.jpg)

![Three defenders try to stop senior point guard Hope Edwards before the ball leaves her hands. The girls basketball team faced Liberty Hill on Feb 21, losing 58-40. “[My season was] definitely bittersweet,” Edwards said. It's definitely sad [because] I'm gonna miss all my teammates, my coaches and just the whole CP environment.”](https://cphswolfpack.com/wp-content/uploads/2025/03/julia-128-1200x800.jpg)